By Prof NG Yun Hau from the Control, Automation & Instrumentation Division of the HKIE

Interest in green hydrogen is skyrocketing around the world as it is seen as a potential solution in tackling challenges in decarbonising society. Although it has been a recent hot topic , utilisation of hydrogen is not new at all. Many important industrial processes (e.g. steel manufacturing, fertiliser production and food processing) have been using hydrogen as feedstock for decades. It becomes a spotlight because of its new role as energy carrier.

Why green hydrogen has an edge over other forms of hydrogen? To date, hydrogen is predominantly produced from steam methane reformation (grey hydrogen) or gasification of coal (brown hydrogen), in which neither of these processes is carbon-friendly. Using fossil source-derived hydrogen, therefore, offers limited help in achieving the goal of decarbonisation. In the context of decarbonisation, hydrogen is meaningful only when both production and utilisation cycles involve low- or zero-carbon emission. This criterion becomes the main driving force for the development of green hydrogen, which is referred to hydrogen generated using renewable energy.

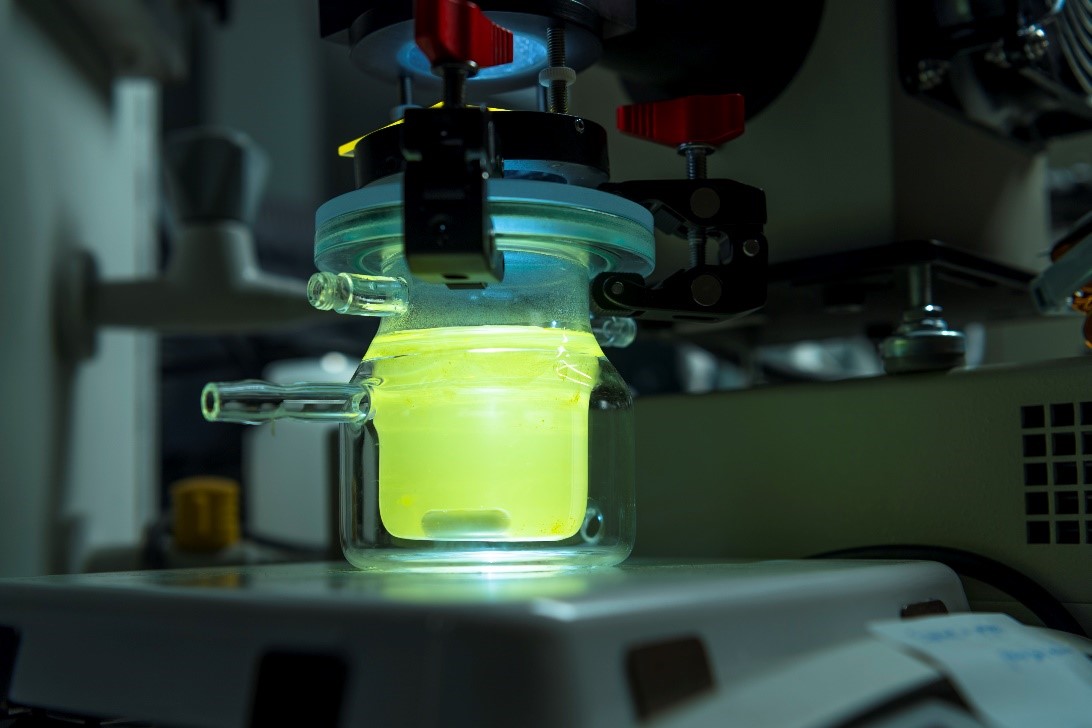

Where does green hydrogen come from? Intermittent renewable power, such as solar or wind, can be integrated to drive the electrolysis of water. This renewable electric current splits water into hydrogen and oxygen via an electrolyser. The steady downtrend in cost of solar and wind electricity is one of the reasons for the rapid growth of green hydrogen. It also benefits the photovoltaic and wind power sectors because the distribution and storage of these intermittent renewable electricity in the form of hydrogen might be more versatile. Beyond this photovoltaic/wind turbine-powered electrolysis of water, photocatalytic technology is another potential option in producing green hydrogen. Photocatalysts are semiconductor powders capable of absorbing sunlight and directly triggers the chemical decomposition of water into hydrogen and oxygen. 100m2-scale of photocatalytic panel has been installed and demonstrated in Japan to produce solar hydrogen from water, without the need of external electricity input. Hong Kong is supporting the development of both technologies through exploring their suitability in local environment.

How it can be applied in different areas ? Traditionally an important industrial feedstock, green hydrogen has found new roles in energy-related applications to lowering carbon footprint. In Hong Kong, hydrogen is already a main component in the gas mixture supplied to households through city-wide pipelines. Transforming from current practices to include higher proportion of green hydrogen will constructively decarbonise our society. Green hydrogen can also be used with fuel cells to generate electricity for mobile and stationary applications. In Hong Kong’s Climate Action Plan 2050 released in 2021, hydrogen fuel cell vehicles are considered an option of green transportation. Subsequently, we have seen the debut of hydrogen-fuel cell bus in Hong Kong this year. To certain extent, fuel cells function as batteries, in which hydrogen and oxygen (from air) are fed to the anode and cathode of fuel cells respectively. Electricity is generated from the conversion of hydrogen, with water as the only by-product. Utilisations of hydrogen to produce electricity through fuel cells are not limited to transportation. Development of stationary fuel cell applications for grid-connected or grid-independent generators are underway. As it can work off-grid, it also offers alternative energy solution to remote areas and may be adopted as emergency energy measures.

Why it is not fully scaled yet? There are a number of obstacles facing the green hydrogen, of which high cost might be the most obvious one. Currently, green hydrogen costs three-to-six times more than that of grey hydrogen. It is also more expensive than natural gas. In addition, the lightness and flammability of hydrogen impose other challenges in its handling. Because of low gas density, transportation of pure hydrogen is difficult. It is either compressed (up to 700 times atmospheric pressure) or liquefied (at -253 °C) for transportation over long distances. As the hydrogen molecule is small, it will induce embrittlement of pressurised pipelines. Gas compression, liquefaction and new pipelines (or storage tank) collectively contribute to the high cost of green hydrogen. On a brighter note, the cost competitiveness could be improved in foreseeable future. Prices of electrolysers are coming down rapidly owing to the scale-up of manufacturing and improved efficiency; renewable electricity (mainly solar and wind) to drive the electrolyser continues to get cheaper. Ongoing research is also in place to explore less costly catalysts used in fuel cells. Furthermore, emerging photocatalytic technology may also play a bigger role in the coming years as it doesn’t involve electrolyser, photovoltaic and wind turbine. A tightened regulatory standard to limit emission could be another push for wider adoption of green hydrogen.

Doing nothing about global warming is no longer an option, while developing green hydrogen may create real impact on curbing carbon emissions. Although widespread use of green hydrogen might not be seen in short run, formulating strategies and action plan to facilitate the adoption of these changes should be accelerated right away.

Photo: New photocatalytic technique in producing hydrogen from water under sunlight